In recent years, there has been a growing focus on developing environmentally friendly pollution removal methods. One of the most promising techniques is photocatalytic degradation in the presence of TiO2 nanoparticles. The unique properties of titanium dioxide are used in a range of applications, including the production of modern self-cleaning coatings used in the hygiene, cosmetics and public health sectors.

The water-based self-cleaning coating CoViGuard24h/7 creates an environment in which microorganisms are neutralised by visible light and/or artificial UV radiation. The end products of such degradation are carbon dioxide and water. A surface coated with CoViGuard24h/7 for 30 days shows a cleanliness level close to, and often exceeding, that after disinfection. Luminometer measurements indicate sustained values of <<500 RLU (Relative Luminescence Unit).

The CoViGuard24h/7 product can be applied to smooth surfaces (i.e. metal, glass and plastic) in high-traffic public areas, such as: lift buttons, stair handrails, handles, railings, lifts, parking meters, parcel machines, ATM panels, manually triggered traffic lights, light switches and many others. The technology used could have a positive impact on the comfort of using public places.

The application of CoViGuard24h/7 is extremely simple. Simply spray the product with a trigger on the dedicated surface and after a minute, rub the product in with a microfibre cloth. The product is ready for use, and the surface is ready to be cleaned.

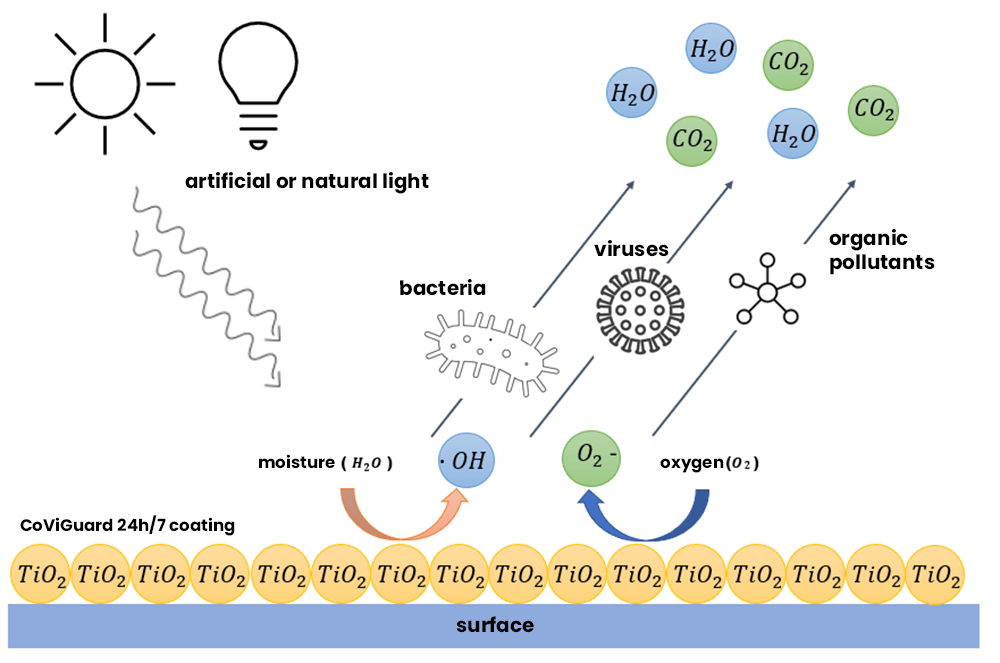

The principle of the CoViGuard 24h/7 self-cleaning coating

The action of the CoViGuard 24h/7 coating is based on a light-mediated photocatalysis process in the presence of TiO2which generates the formation of reactive oxygen species (ROS), mainly O2-∙ and ∙OH responsible for the decomposition of organic pollutants, bacteria and viruses by oxidising them to H2O and CO2. RFTs decompose organic matter causing disruption of the cell membrane followed by loss of essential functions such as respiratory activity leading to cell death. As a result of interaction with radiation, dirt accumulated on hydrophilic surfaces coated with nano-TiO2 is decomposed, loses its adhesion and can be easily washed off. The photocatalytic production of hydroxyl radicals by TiO2 accelerates the breaking of chemical bonds in volatile organic compounds (VOCs), making the gases harmless to humans. In addition, they clean the air of unpleasant odours (e.g. urine, faeces, nitrogen oxide, formaldehyde, petrol).

EVALUATION OF SURFACE CLEANLINESS

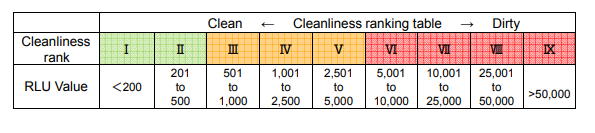

The luminometer is used for instant monitoring of microbiological cleanliness and hygiene of work surfaces, hand cleanliness and water by measuring the bioluminescence produced during the enzymatic decomposition of ATP, AMP and ADP. The result is visible after only a few seconds.

.

Interpretation of results:

Examples of surface cleanliness values measured with a luminometer:

-

13,000 RLU - hand

-

16 000 RLU - handle

-

6 000 RLU - ball pen

-

20 000 RLU - WC

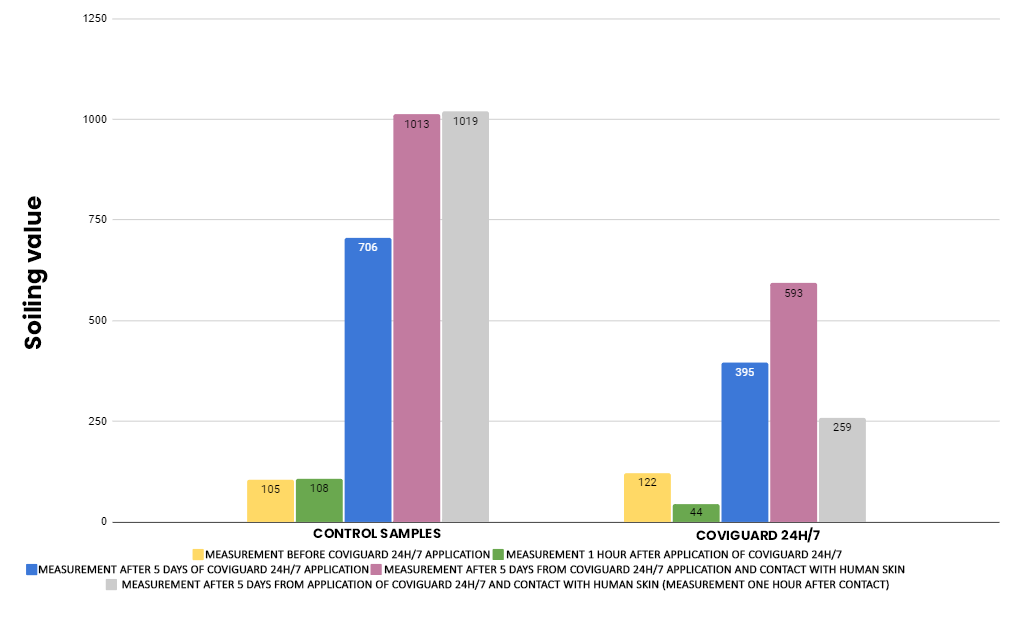

The graph showing the RLU value over time after the CoViGuard24/7 coating has been applied to the glass substrate:

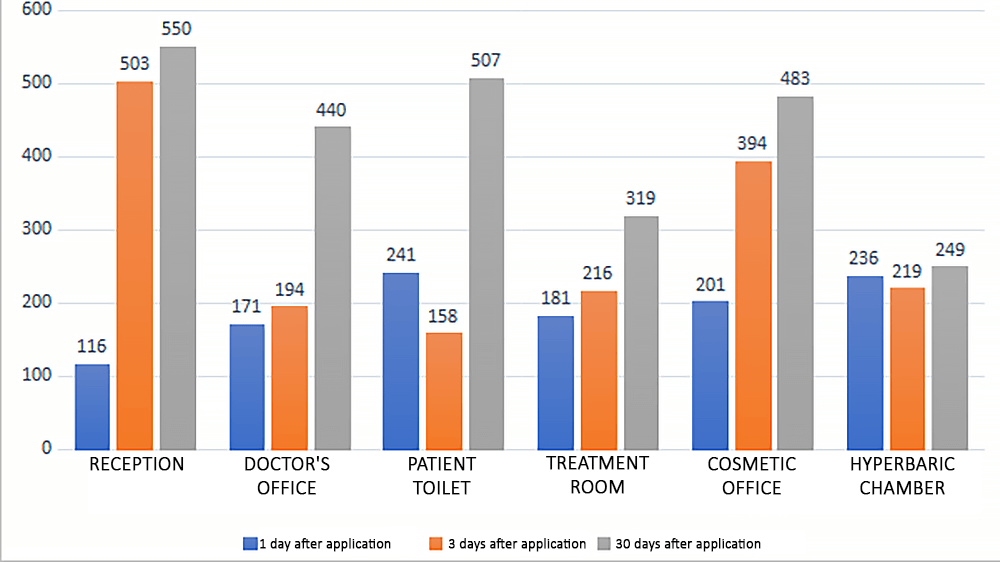

HydroSafeGuard S.A applied CoViGuard 24h/7 coating to the areas that are particularly exposed to organic contamination:

- Health Clinic in Bałuty District at 104 Limanowskiego Street, 91-042 Łódź

2. Health and Beauty Clinic at 149 Aleksandrowska Street; 91-154 Łódź

The results of measurements carried out 1, 3 and 30 days after the application of CoViGuarda24h/7 are as follows:

ORDER EXECUTION:

-

Possible pack sizes: 0.5l HDPE bottle with trigger; 5l HDPE canister

- Minimum order is: 1 pallet

|

package |

number of packages on the pallet |

number of litres on pallet |

|

HDPE 0.5l bottle with trigger |

780 |

390 |

|

5l HDPE canister |

114 |

570 |

- Order execution:

|

Quantity |

lead time |

on condition that |

|

less than 10 tonnes |

10 business days |

account credited / money transfer confirmation sent |

|

over 10 tonnes |

consignment of 1 tonne per day or 10 tonnes every 10 business days |

account credited / money transfer confirmation sent |

TECHNICAL DATA

-

The thickness of the coating applied once is 4µm

Mechanical resistance tests

Tests performed by Anticorr

-

The adhesion test using the cross-cut method according to EN ISO 2409 indicates that CoViGuard24h/7 has perfect adhesion to the following substrates: metal, glass, plexiglass. 3.

3. Scratch resistance test using a TestAn brand sclerometer with a tungsten carbide scriber according to EN ISO 1518-1 indicates that:

- the coating applied to metal at a force of 0.5N is scratchable, while at a force of 1N and 2N it peels off,

- coating on plexiglass at a force of 0.5N is scratchable, at 1N and 2N it peels off,

- coating on glass at a force of 0.5N, 1N and 2N is peeled off.

-

Coating hardness test using a Koening/Persoz pendulum hardness tester in accordance with EN ISO 1522 shows that:

- CoViGuard24h/7 applied to metal enhanced the surface hardness,

- CoViGuard24h/7 on glass slightly reduced the surface hardness.

Ageing tests

Tests performed by Anticorr

- 30h of exposure in the ageing chamber corresponds approximately to 30 days of natural exposure to sunlight,

- for each of the following tests, measurements were taken before and after 30h exposure in the TestAn Xentest 2200 chamber,

- all measurements were made on certified Lenet cards.

-

Colour difference measurement performed according to EN ISO 7724-3:2013 using the TestAn DT-110 colorimeter, indicates that the coating is perfectly transparent and a standard observer will not notice the colour difference.

-

Gloss measurement performed according to EN ISO 2813:2014-11 using the glossmeter TestAn DT-060, indicates that coating a high-gloss surface with CoViGuard impregnate slightly reduces its gloss, while the effect of UV radiation gradually diminishes this effect.

-

The opacity measurement carried out in accordance with EN ISO 2814:2016 using the TestAn DT-100 reflectometer, indicates that the coating has high transparency.

Antimicrobial activity

Study performed by the Technical University of Łódź

The microorganisms used in the study were sourced from the American ATCC Pure Cultures Collection and stored in the ŁOCK 105 PŁ Pure Cultures Collection. These included gram-negative bacteria Escherichia coli ATCC 10536, gram-positive bacteria Staphylococcus aureus ATCC 6538, yeast Candida Albicans ATCC 10231 and mould Aspergillus Niger ATCC 16404. The microorganisms are divided into different groups (bacteria, fungi) and exhibit distinct morphological, physiological and sensitivity profiles to biocides.

-

The antimicrobial activity of the repellent was initially tested against the specified microorganisms using the well and disc method. The microorganisms were inoculated using the depth method onto microbiological media. TSA (Tryptic Soy Agar, Merck) (bacteria), MEA (Malt Extract Agar, Merck) (yeasts, moulds) were incubated at 37°C for 24-48 hours (bacteria, yeasts) and 27°C for 5 days (fungi). The efficacy of the repellent was evaluated using two distinct methodologies: the well method and the disc method. In the well method, cork borers were used to create wells into which 250ml of repellent was added prior to incubation. In the disc method, 10ml of varnish was applied to sterile blotting paper discs. Following the incubation period, the zones of growth inhibition were measured and the results were reported in millimetres. Growth inhibition of 10 mm or more was considered to indicate high activity. For the well method, the value was given after subtracting the diameter of the wells.

-

The antimicrobial activity of metal and glass plates coated with repellent against 2 microbial strains S. Aureus, C. Albicans was evaluated. Tests were performed using a quantitative method on 4 cm2plates prepared by the manufacturer; tests were performed against S. Aureus for glass plates and against S. Aureus, C. Albicans for metal plates. A microbial inoculum with a known density of 5×109 cfu/ml (S. Aureus) and 7×107 cfu/ml (C. Albicans) was prepared and applied to the surfaces of the plates in a volume of 100 ml. Microbial counts were assessed immediately after application to the plate and after a 24-hour incubation at 37°C.

-

The antimicrobial activity of impregnated metal plates (four samples and a control sample) was investigated as part of our product development process. The plates were exposed to air microflora for a period of five days. Following this period, the number of bacteria and fungi was determined by imprinting on TSA (bacteria) and MEA (fungi) media and incubating them under conditions of 37°C for 24 hours (bacteria) and 27°C for five days (fungi). After this time, the colonies grown on the plates were counted, and the results are expressed in colony-forming units (cfu) per 4 cm2 of plate surface.

-

Quantitative microbiological tests were also conducted on two entrance handles in public space before and after disinfection with repellent. The disinfection process was completed on the handle with repellent by application using the sputtering method. Once the handle had been sufficiently wetted with repellent, it was wiped with a sterile cloth and left to dry for five minutes. A sample was then taken by swabbing. A swab was taken from the second handle without prior disinfection. Samples were taken with a sterile swab and suspended in 10ml of sterile 0.85% saline, shaken for five minutes, and then seeded onto sterile plates. The plates were inoculated with semi-solid TSA medium and incubated at 37°C for 24-48 hours. The number of colonies grown was counted, and the result is given in CFUs per handle.

CONCLUSIONS:

Re 1

The impregnate was found to be effective in inhibiting the growth of S. aureus, E. coli bacteria and C. Albicans yeast, irrespective of the test method employed. The impregnate demonstrated high activity against the A. Niger mould, with a growth inhibition zone of 15 mm in the disc method and 40 mm in the well method. The tested impregnate exhibited greater activity against fungi than bacteria, with the following order of sensitivity: A. Niger, C. Albicans, S. Aureus, E. Coli.

Re 2

Table 1. Reduction in the number of microorganisms on the surface of metal and glass plates with applied repellent after 24 hours of exposure with microorganisms

|

Type of sample |

Number of microorganisms on the plate surface [cfu/4 cm2] |

Reduction in number of microorganisms [%] |

|

Control metal plate |

1,98109 |

– |

|

Metal plate with impregnation S.aureus |

8,00107 |

95,9% |

|

Control metal plate |

6,60107 |

– |

|

Metal plate with impregnation C.albicans |

4,00104 |

99,9% |

|

Control glass plate |

9,00108 |

– |

|

Glass plate with repellent |

7,20107 |

92,0% |

– control, not applicable

The results demonstrated that both test microorganisms exhibited inhibited growth after 24 hours of exposure to the metal and glass plates coated with the repellent. The antimicrobial effect was more pronounced for C. Albicans yeast (99.9% reduction in cell count) than for bacteria (95.9% reduction). The number of C. Albicans cells on the metal plate was reduced by three orders of magnitude on a logarithmic scale. For S. Aureus bacteria, a reduction of approximately 1.5 logarithmic orders was observed.

Re 3

Table 2. Antimicrobial activity of impregnated metal plates against bacteria and fungi after exposure for 5 days to air microflora - tests by imprint method

|

Samples of impregnated metal plates |

Number of bacteria on plate surface after 5 days of incubation [cfu/4 cm2]. |

Number of fungi on the plate surface after 5 days of incubation [cfu/4 cm2]. |

|

Control |

59 |

10 |

|

1 |

38 |

– |

|

2 |

– |

4 |

|

3 |

35 |

2 |

|

4 |

11 |

1 |

– no growth

Following five days of exposure of the plates (control and impregnated) to air microflora, a reduction in the number of microorganisms on the surface of the varnish-coated plate was noted. The number of bacteria decreased significantly, from 59 cfu/4 cm² (control) to 11 cfu/4 cm² (Sample 4), and from 35-38 cfu/4 cm² (Samples 1 and 3). The number of fungi declined from 10 cfu/4 cm² (Control) to 1 cfu/4 cm² (Sample 4) and 2-4 cfu/4 cm² (Samples 2 and 3). The results demonstrate that the repellent inhibited the growth of both bacteria and fungi on the surface of the metal plate.

Re 4

The results of the microbiological examination of 2 entrance handles in the public area before and after disinfection with repellent are shown in Table 3.

Table 3. Microbial counts before and after disinfection of 2 x handles with repellent - tests by swab method

|

Handles |

Microorganism count on the handle surface [cfu/handle]. |

|

Handle 1 before disinfection |

5,0×102 |

|

Handle 1 after disinfection |

0 |

|

Handle 2 before disinfection |

6,0×102 |

|

Handle 2 after disinfection |

0 |

-

- No growth in test environment (in a volume of 10 ml and culture of 0.1 ml)

Application of the repellent to the doorknobs for a period of 5 minutes resulted in a reduction in the number of microorganisms by more than 2 logarithmic orders (the number of microorganisms decreased to a level undetectable under experimental conditions).

Antimicrobial activity

The test was performed by Proteon Pharmaceuticals

The test used a suspension of bacteriophages with a titer of: 2.08 x 109 CFU/ml

Incubation 30 min

| Phage titer (PFU/ml) | |

| Control-phage suspension | 2,81 x 10^8 |

| Repellent-coated metal plate | 9,52 x 10^7 |

| Metal plate not coated with repellent | 2,09 x 10^8 |

Incubation 4 h

| Phage titer (PFU/ml) | |

| Control-phage suspension | 2,32 x 10^7 |

| Repellent-coated metal plate | 1,43 x 10^7 |

| Metal plate not coated with repellent | 1,70 x 10^8 |

Summary of the test of the antiviral effect of impregnation based on the use of bacteriophages:

- The bacteriophage titer used was 2.08×10⁹ PFU/ml.

- The sample with the metal plate coated with the test repellent demonstrated a 54.45% reduction in bacteriophage titres relative to the sample with the metal plate not coated with the test repellent, following a 30-minute incubation period with bacteriophages.

- The metal plate coated with the test repellent demonstrated a 91.59% reduction in bacteriophage titres relative to the metal plate sample not coated with the test repellent after incubation of both samples with bacteriophages for four hours.

- After a 30-minute incubation period, the metal plate sample coated with the test repellent demonstrated a 95.44% reduction in bacteriophage titer relative to the initial inoculum.

- After four hours of incubation with bacteriophages, the metal plate coated with the test repellent demonstrated a 99.32% reduction in bacteriophage titer compared to the metal plate not coated with the test repellent.